How Smart Hard Hats Improve the Safety and Efficiency of Oil & Gas Workers

The oil and gas industry, being one of the oldest participants in the industrial revolution, has seen a lot of disruption in the technological arena. Whether it’s in identifying, extracting, or producing raw materials on offshore or onshore operations, or downstream services like fuel delivery to the consumers, the industry has witnessed a significant evolution. Both Onshore and Offshore oil rigs are implementing the latest technologies in the form of new types of equipment such as hoisting systems, cranes, turntables, pumps, and large engines.

Additionally, E& P companies are integrating IoT enabled devices that monitor and keep track of every operation seamlessly. Downstream companies are adopting on-demand fuel delivery services to their business strategy.

In this article, we’re going to shed some light on a much-discussed, and widely adopted IoT enabled technology called – the smart hard hat! We’ll cover each aspect of the smart hard hat and how it is taking its place in the O+G industry. We’ll also understand why implementing this tech into oil fields would lead to increased safety and efficient operations.

With further ado, let’s start and explore this pioneering technology.

Why Do Smart Hard Hats Deserve Their Inclusion in Oil & Gas Sites?

Exploration & Production (E & P) companies are usually associated with heavy machinery & operations that require special attention and frequent maintenance. Notably, in any upstream operations, workers’ safety is an important matter.

Upstream operations pass from finding hydrocarbon reservoirs, drilling oil and gas wells, and extracting raw materials to selling them to be refined by other companies into products such as gasoline, which demands meticulous monitoring of operations. However, sometimes due to practical, procedural and operational processes, it becomes gruelling to coordinate with your staff and workers.

Here is where smart hard hat comes in!

What is a Smart Hard Hat & How Does it Work?

‘Smart Hardhat’ as the name suggests is a smart device that could help company owners and workers in many ways. The whole device gets embedded with sensors that track surrounding quantities and measures the data accurately for the betterment of its wearer and the one who is monitoring. These sensors can be anything from a temperature tracker to an air quality checker.

A smart hardhat is awash with various sensors like a smoke detector, barometer, SOS panic, gyroscope, body temperature sensor, GPS, and humidity sensor. Sensors continually detect particular quantities and send a signal to the owner as well as its admin – whether the controlled parameters are out of their defined range or not! If any parameters indicate a variance beyond safe limits, the signal triggers alert to the wearer and administrator about the situation. Hence, many hazardous incidents can be avoided.

Here is how these sensors work!

- Temperature Sensor: This sensor lets the smart hardhat track the temperature variation of surrounding the area. It continually sends the signal about the changes happening in the temperature.

- Humidity Checker: As the name suggests, the sensor facilitates in knowing the moisture in the air. Therefore, if at the site, specific humidity is required, a smart helmet helps to monitor that.

- GPS: Today, most smartphones utilize GPS to give you the exact location of your interest. This GPS module tracks the wearer precisely.

- Map Navigation: Workers in the oil field, especially new ones, can navigate their way through the site very quickly using the navigation capability of the smart hardhat.

- SOS Panic Button: The panic button installed on the device comes to aid when there’s any medical emergency.

- Proximity sensor: This sensor helps the wearer to stay away from the objects that they’re not allowed to touch or risk going near.

This hardhat works on IoT (Internet of things) technology where software, network connectivity, each device continually communicates with each other without any human interaction. They get connected through any internet connection, and as stated earlier, it adjusts its values according to the situation.

What is the Role of IoT Enabled hardhat in the Oil & Gas industry?

As we mentioned earlier, the smart hardhat comes handy in safety issues and the need for effective resource management. The benefits of a smart hat don’t stop here. It also monitors the health of your valuable workers.

If a worker is heading unknowingly toward a restricted area or any dangerous place in the site, it would instantaneously alert him about it. Nowadays, these devices get furnished with groundbreaking headsets. That allows the workers to communicate efficiently through their reporting authority as well as related workers. It also reduces the unwanted noise that’s coming from the site.

The panic button installed on the hat lets people take precautions in case of any emergency.

Respiratory hazards can also get avoided by forecasting any leakage or defect in any of the instruments at gas sites. Workers could save themselves getting in contact with dust, fumes, mists, gas, smoke, sprays, vapours, or other hazards.

It’s not only manual workers, but E& P company management can also find smart hard hats promising due to their resource management capacity.

There are hundreds or even thousands of workers in each company working on onshore and offshore sites at their allocated location. To manage each and everyone could be challenging for any manager. For higher production and output in the oil field, effective monitoring and management become vital. A smart hard hat comes as the best solution for this situation. You might ask how?

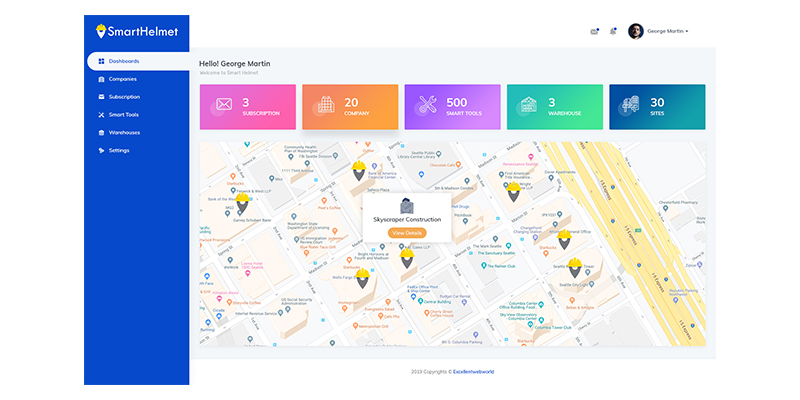

Well, the smart hardhat gets integrated with GPS modules that always sends a signal to the software that is managed by the higher authority person on the site. So every wearer can be tracked with their live location. A manager will be able to identify a particular worker and know whether he is at his allocated work location. Or if he is idling away his time doing unnecessary things — any extra insights into these kinds of data aids in better management of assigned workers.

Conclusion

By 2025, it’s forecasted that there’ll be more than 21 billion IoT devices. More and more industries are adopting these IoT enabled solutions to enhance their businesses. The oil & gas industry will be one of the most affected sectors by IoT and other technologies. The smart hard hat has penetrated in multiple areas where safety and management is the prime concern. It remains to be seen how soon upstream and midstream companies install such technology for their betterment.

IoT has truly done wonders in the world. From home automation to helping workers safeguard their time on the work site is truly incredible.