Rather than just the science, this post is focused on practical questions such as: What do petroleum engineers do? We cover the common job profile variants and tasks.

What is petroleum engineering?

Petroleum engineering is the branch of engineering that develops and implements ways of extracting crude oil and natural gas. Petroleum engineers play an essential role in every stage of the upstream process: they are the ones who evaluate the results of exploratory drilling and decide whether drilling a production well is commercially justified. Then they are the ones who find the most cost-efficient way to drill that well and monitor its performance once the oil starts flowing.

Petroleum engineers design the equipment that is used to pump oil and gas from the ground, and they are also the ones who devise ways to maximise production by employing various extraction methods. In addition to this, petroleum engineers are in charge of making sure the whole production process runs smoothly, and all equipment operates as it should. Finally, petroleum engineers evaluate the production from a well in terms of quantity and quality to make sure they are both optimal.

With so many responsibilities, petroleum engineering has several subdivisions that focus on different parts of the oil and gas extraction process.

Reservoir engineers are the experts who evaluate the oil and gas reserves of a deposit and determine the best drilling locations. Their job is to find out as much about the deposit as possible using geological survey data and testing results to make sure wells get drilled where there is the most oil and gas to be recovered, and that this gets done cost-efficiently.

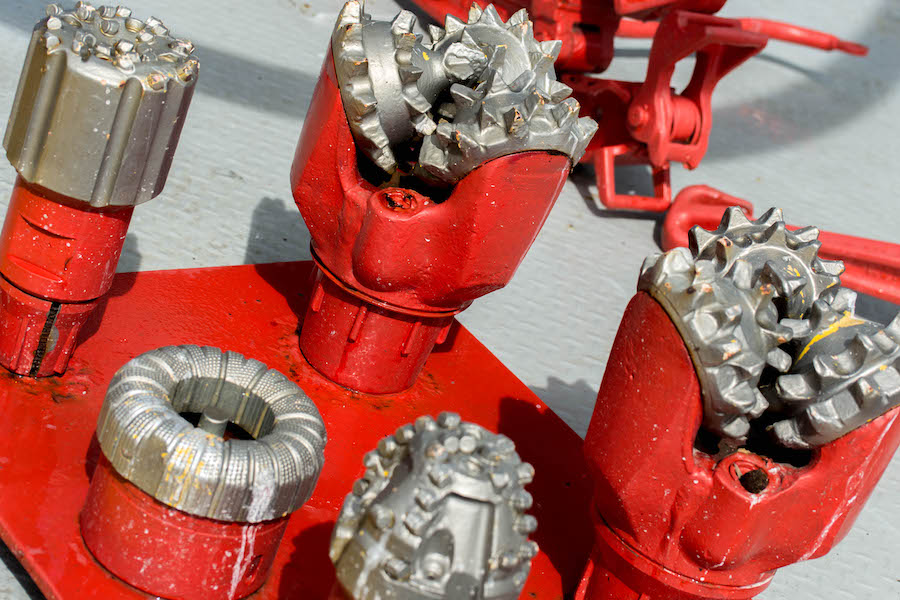

Drilling engineers are in charge of the first stage in oil and gas production: well design, including the equipment to be used to drill the well, data analysis, well completion, and, eventually, abandonment. Drilling engineers’ work overlaps with that of completion engineers.

Completion engineers are in charge of taking a well from getting drilled to the start of commercial production of oil and gas. The completion engineer makes sure the well is built correctly, using the appropriate materials and equipment, and that it will operate properly as well.

Subsea engineers specialise in the planning and installation of any production and transportation equipment below the sea surface at an offshore platform. Rig installation, wellhead construction, and pipelines are the area of expertise of the subsea engineer.

Production engineers step in once the well is completed, and commercial production begins. The main focus of their work is two-fold: 1) monitoring the flow of oil and gas, and 2) Implementing methods for boosting that and improving the efficiency of production.

What qualifications do you need to become a petroleum engineer?

A bachelor’s degree in petroleum engineering is the basic qualification level you need if you want to start a career in this field. To prepare for that degree, focus on science subjects in high school is essential, with a side of social sciences to help develop communications skills that are also part of a petroleum engineer’s skill set as work involves extensive communication with various people and agencies.

Following the successful completion of a bachelor’s degree in petroleum engineering, many universities also offer a master’s degree in the subject area, and there are also additional qualification opportunities in the United States from the Society of Petroleum Engineers. The SPE awards certifications to those who complete its additional training course.

In the United States, in addition to completing a bachelor’s degree in petroleum engineering at any of the schools, one also needs to earn a state license if they are to work as self-employed engineers. The licensing procedure involves passing an exam and logging in four years of qualifying work. The process ends with another exam. There are also state-specific requirements.

In the UK, universities that offer petroleum engineering degrees require three A levels, preferably in maths/physics and sciences, as well as five GCSEs, also featuring maths and sciences. Some accept level 3 vocational qualifications, as well. For graduate and postgraduate degrees, a minimum 2:2 undergraduate degree in any of the following: chemical, civil, mechanical, and petroleum engineering, and earth sciences, is required.

For work offshore, petroleum engineers in the UK also have to pass an exam in basic offshore instruction and emergency training, or BOSIET.

Postgraduate qualifications are not necessary to enter the oil and gas industry as a petroleum engineer, but it’s worth noting many oil and gas companies do expect a postgraduate qualification, which also has an impact on pay.

After earning the required degree, a petroleum engineer would start work under supervision from a more experienced colleague. Additional training at the company is also a common practice for new engineers.

Those with a degree in chemical or mechanical engineering can also go on to specialize in petroleum engineering after earning a bachelor’s degree.

The skillset of a petroleum engineer

Problem-solving: all engineers are problem solvers, and petroleum engineers are no exception, especially since unsolved problems in this industry could be quite costly.

Analytical skills: problem-solving requires the ability to analyse vast amounts of data, and while automation is taking some of the load off, it is still up to the engineer to make sense of all that data and decide how to use it.

Mathematics: data analysis and problem-solving in engineering require an excellent versing in maths as a fundamental tool in everyday work. Whether it concerns oil well construction, oil flow improvement, or any of the dozens of other tasks an engineer has to perform in their work.

Communication skills: Oil and gas production is teamwork in a heavily regulated industry. What’s more, this teamwork involves expensive equipment and infrastructure. Excellent communication within the team and with relevant government agencies is essential for ensuring the success of projects that commonly cost tens of millions of dollars at the very minimum.

IT skills: Information technology has become an integral part of the oil industry, and this part will only grow with the increasing adoption of big data analytics, automation, and artificial intelligence. In this context, IT expertise has become essential for petroleum engineers.

What does a petroleum engineer do?

- Discover new oil and gas deposits.

- Devise the best way to exploit deposits, including best drilling locations and the number of wells.

- Design the equipment that will be used to drill the wells and extract the oil and gas.

- Develop drilling and completion plans.

- Monitor drilling and completion.

- Monitor well flow and find ways to maximize it profitably.

- Analyse well data and track daily costs.

- Determine the optimal amount and method of injecting water, chemicals, and sand into the well to achieve higher flows at cost.

- Recommend changes to extraction methods to boost cost-efficiency.

- Develop enhanced oil recovery methods when necessary.

- Continually evaluate well performance.

- Make sure production operations comply with safety and environmental regulations.

- Oversee well abandonment when its productive life ends.

- Keep relevant stakeholders informed about progress, including management, contractors, and energy and environmental authorities.

How much does a petroleum engineer make?

Petroleum engineers are in strong demand despite a shift from fossil fuels to renewables in the energy industry. While there is demand for oil and gas, there will be exploration and production and petroleum engineers are essential in both segments of the upstream sector. Authorities and industry research companies are warning a talent shortage is emerging.

Petroleum engineers are already quite well paid in most countries, and the talent shortage will undoubtedly make them even better paid.

In the United States, the world’s largest producer of oil, the average salary ranges between a little over $100,000 annually to almost $120,000. Including bonuses and profit-sharing, the figure could increase substantially.

Hourly wages in the U.S. oil industry range from $36 to $90, depending on the state where the petroleum engineer is working, their experience, and the position they have at the company.

The highest-paying state, unsurprisingly, is Texas. According to data for 2015, Texas led the rank of highest-paying states for petroleum engineers with an average annual salary of $164,000. The oil industry is a dynamic one, and things change fast as oil prices vary. Still, Texas remains the hottest spot in the U.S. oil industry with its two colossal shale plays, so it will likely stay the best-paying state for petroleum engineers until the so-called second shale revolution runs out of steam. In evidence of this, new data from Indeed shows the average annual salary for a petroleum engineer in Texas was almost $137,000. That was 45% over the national average.

In the UK, petroleum engineer salaries average almost £52,000 annually, according to Indeed data. According to Prospects, the wages of a drilling engineer begins at between £25,000 and £45,000 and could reach £40,000 to £100,000, depending on the experience needed, and the size of the company employing them.

These salary ranges, however, are for engineers working full-time for an E&P. Self-employed engineers can—and often do—make a lot more. There is a striking difference between working for a large oil company full-time and working for it as a contractor or consultant. In the latter case, you could make a lot more (multiples of the employed take-home pay).

Jobs in offshore exploration and development, for example, are generally a lot more lucrative than onshore assignments. A subsea engineer on an offshore platform could earn anywhere between $75,000 and $188,000 annually. A drilling engineer employed on a deepwater rig could make up to almost $200,000 in base pay plus bonuses. Yet this is considerably less than what an offshore drilling consultant would make: $143,000 to $305,000.

Working overseas can also be more lucrative than working at home, even doing the same job as a petroleum engineer. Big Oil companies active across the globe pay generous compensation for working overseas in addition to the basic pay, any bonuses the engineer earns, and profit-sharing allocations. What’s more, they pay even more to contractors or consultants.

A drilling engineer working for one of the supermajors could make almost $80,000 working for the company in Saudi Arabia. As an independent contractor, however, the same engineer could make more than $300,000 working with the same company in the Middle East.

Profit-sharing additions are also worth mentioning when it comes to the money a petroleum engineer can make. In Saudi Arabia, for example, the average salary of a petroleum engineer is equal to about $70,500. However, this is just the principal salary. In addition to it, a petroleum engineer could make about $5,900 in bonuses and another $8,000 in profit-sharing allocations.

As in other industries, pay depends not just on location or contractual terms but on experience as well. The longer you have worked as a petroleum engineer, the more you would be paid. For example, in Indonesia, the starting salary for a petroleum engineer with zero to two years of experience is about $630 per month. However, an engineer with 15 to 20 years of experience would get $1,440 per month, and those with experience of over 20 years would get over $1,700 per month.

In China, work experience is the most critical factor for employers when they determine the pay of the petroleum engineers they hire. The pay difference between an engineer with up to two years of experience and one with experience of between two and five years is 46%: $2,240 a month for the former versus $3,270 for the latter.

Across the globe, a drilling consultant would make more than a drilling engineer on an offshore rig because of their supervisory responsibilities. To become a drilling consultant, however, you need at least ten years of experience, both as a permanent employee at an oil company and as a self-employed consultant. In short, experience pays well.

There has been growing concern recently that the profession of a petroleum engineer is dying out because of the shift to renewable energy. A lot of people are in two minds about whether to pursue petroleum engineering or another engineering degree. Indeed, over the long term, the industry might need fewer engineers than it required in the 1970s, for example. However, there is still a shortage of skilled petroleum staff looming over the oil and gas industry, and this means petroleum engineers will continue to be in demand for the foreseeable future.