Well Operation Case Study

This project was to conduct a PFEA injector and water well design review. The end purpose was to have a cost-effective injector design that meets industry standards and well integrity requirements. This work was carried out for a State Oil Company in the Northeast region of South America. This company produces approximately 25,000 bopd.

Background

A Polymer Flood (PF) pilot project achieved favourable results, and the proposal for commercial-scale application was subsequently approved in 2013. However, due to the subsequent downturn in oil price development and indispensable budget constraints, the expansion was put on hold.

To improve the IRR of the PF expansion, surface and subsurface studies were initiated. One of the studies involved injector wells’ (re)design and the selection of wellheads required for the polymer expansion.

At the time, three (3) injectors were in operation, in which annular packers had been installed to protect the casing from the injected polymer. However, all three injectors had been shown to have undesired casing pressures. Based on the learning and the desire to lower the CAPEX of the polymer flood project, a new design for injector wells and wellhead was developed.

To ensure that the new design met all requirements. Having the designs reviewed by an external expert on the subject was recommended.

A project was proposed to the Completions SME to Deliver a cost-effective injector well design to meet industry standards and well integrity requirements.

Objectives

The main objective was to validate whether the design was according to industry standards and, if required, identify which modifications were needed to meet client objectives.

Scope

Review, commentate, and, where applicable, redesign the proposed injector and wellhead designs for suitability, functionality, and cost-effectiveness.

Provide written justifications for design improvements according to industry standards.

Deliverables

A final report in digital format, which included the following:

· An executive summary

· A technical summary

· A description of the analysis methodology, a short description of the workflow used and relevant assumptions

· Results and findings

· Conclusions and recommendations

A new well design was agreed upon, and recommendations as to potential equipment providers were also delivered as an additional scope to assist the local engineers in reaching out to the available new technologies.

Result

All past but relevant documents, including an Injection Well Design review conducted by a major service company and an Injection Well design for CO2 & Polymers, were carefully reviewed. There were also memos relating to possible casing leaks and other findings stretching over the previous ten years.

A list of recommendations and minor changes were suggested as follows:

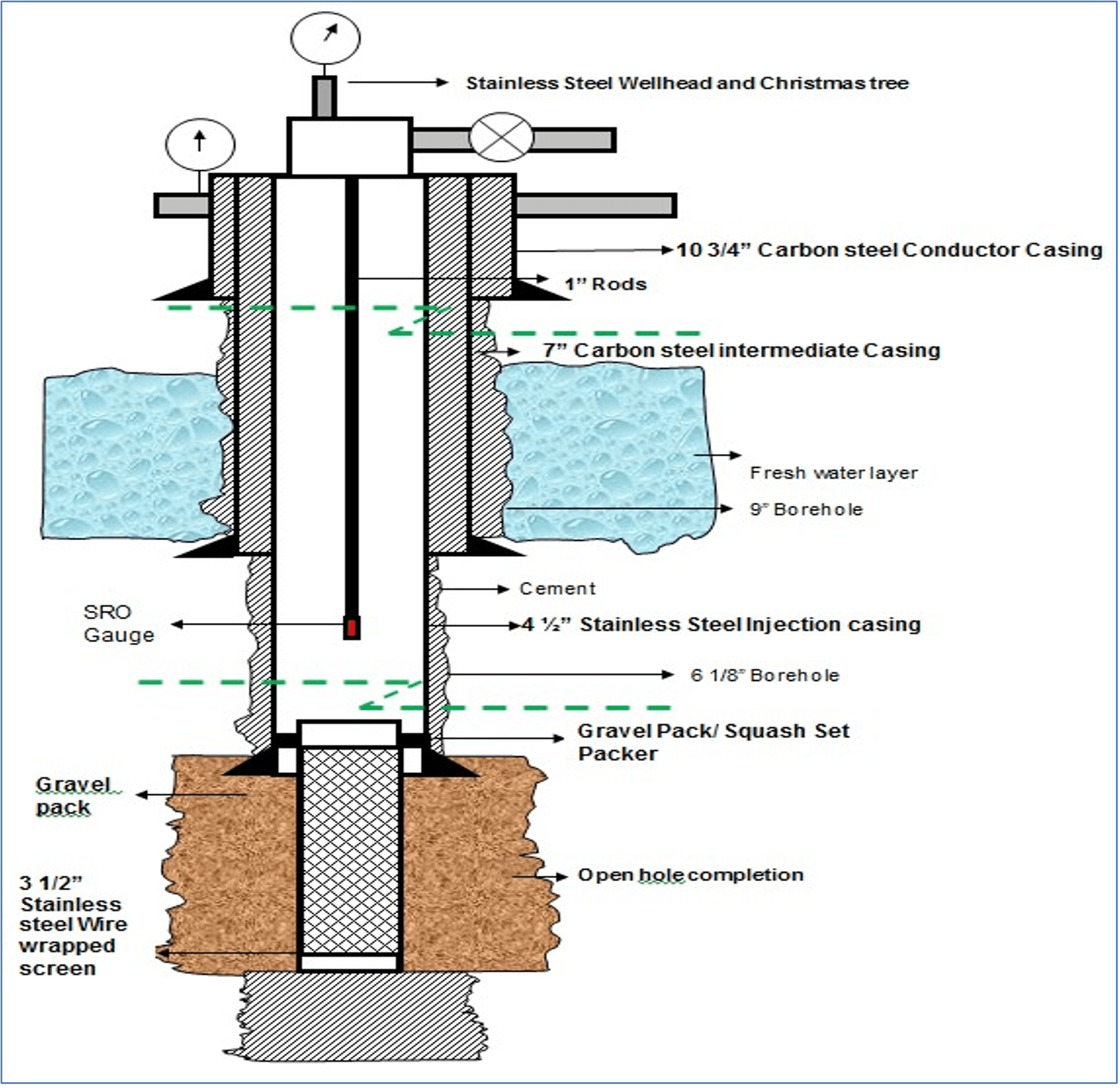

- Add a swellable elastomer-type packer to the shoe joint of the 7″ Carbon Steel Casing to provide cement assurance. The casing shoe should also be placed 100 feet below the water zone.

- Consider some form of centralisers for the rod string to protect the SRO from undue movement.

- Ensure the SRO cable is compatible with all injection or produced fluids.

- Ensure the SRO Cable Clips are compatible with all injection fluids.

- Consider installing a 3 1/8″ 2M gate valve with RX 31 suitable SS gaskets.

- Ensure all components of the wellhead system are compatible with all fluids.

- Consider longer pressure tests for cement verification and ensure all charts are witnessed and accepted by Company Representative.

- Consider all Completions Operations Supervised by a Competent Completions Supervisor that is aware of the importance of testing and verification.

- Ensure contingency plans are in place if any operation does not meet planned objectives.

- Finally, consider the lifecycle of the well and how this well could have remediation or a workover carried out.

A detailed technical summary was provided. All components were reviewed for their suitability in accordance with current industry standards, and where necessary, in the absence of such standards, good oilfield practice has been applied.

Detailed recommendations covered the following topics

- Applicability of the Wellhead

- Well Integrity

- Well barrier plan

- Verification of the final well barrier

- Contingency planning for well construction

- Well design deliverables, reporting and documentation

- Barrier verification

- Cement

- Casing & Tubular connections

- Well handover information

- Well operational phase objectives

- Well monitoring and surveillance

- Monitoring and surveillance frequency

- End of well life review

- Protection of Freshwater Zones

- Resistance to Corrosion and to Avoid Polymer Contact with Carbon Steel

- Cost Effectiveness

- Durability

Review Process

The review process for this project involved a detailed review of the provided reports, teleconference calls and email communication. This was to allow a full understanding of the project and to ensure that there was a clear understanding between all parties. Further considerations taken were from both personal experience and industry experience that the reviewer has been involved with.

The supplied documents demonstrated to the reviewer that there had been considerable work undertaken by a number of parties over the last 9yrs and that the majority of scenarios have been considered.

Weekly technical discussions were carried out with the client during the period of this review process to allow complete knowledge sharing in both directions.

Conclusions & Recommendations

As a result of the reviews and consideration of the selection criteria, it was recommended to proceed with Option 2 of three possible scenarios. These three scenarios were carefully designed and modelled, and were submitted to complete scrutiny in respect of the anticipated pros and cons. The design and specifications of a custom-made wellhead solution were submitted alongside all of the reporting.

Work completed by: Gordon Duncan

Well Operation Case Study

Well integrity, Completions, Interventions & abandonment Expert

Gordon Duncan

Do you think that Gordon has something to offer for your project? Perhaps you have something to offer Gordon?

If so, then fill in this webform and Gordon will be in touch with you as soon as possible.

In the message box, please indicate the reason for the enquiry in simple and precise terms.

Privacy notice: Rest assured that only Gordon Duncan, and up to three integral personnel at drillers.com will see your contact details. We won’t distribute these details or add you to any mailing list without your explicit additional consent.