© Copyright 2024 Drillers.com all rights reserved. Terms & Conditions Privacy & Cookie Policy Web Design

Well Integrity Case Study

An International Oil Company (IOC) in Oman, which is a subsidiary of a large international energy firm, required a thorough review of their Well Integrity Management Standard. Our contribution involved evaluation, training, troubleshooting, systematisation of processes, continued support, and comprehensive documentation, culminating in a well-integrity standard document that encompasses all well lifecycle stages and management.

Background

This client is an International Oil Company (IOC) based in Oman and operates as a standalone business unit of a large international energy company. This IOC required a detailed review of their Well Integrity Management Standard in line with ISO 16053-1, Norsok D10, and MOG SUB04-B01-Guidelines-Wells-Well Integrity. A well-integrity standard document was one of the required deliverables. This contained all the other well lifecycle steps and management. Our input involved reviews, training, problem-solving, systematisation of processes, ongoing support, and complete documentation.

Workshops and Training

In addition to the initial research and planning, we were asked to facilitate workshop days to raise awareness of well integrity and then prepare for the rollout of the well integrity plan.

The objective of these sessions was to provide a comprehensive understanding of well integrity management and its importance. The sessions were divided into two parts – the first part discussed why we need well integrity management, while the second part focused on how we could achieve it.

The first part of the session aimed to provide a broader and more consistent understanding of well integrity and the reason behind the development of a well-integrity management standard. It emphasised the importance of well integrity in ensuring the safety and sustainability of oil and gas operations.

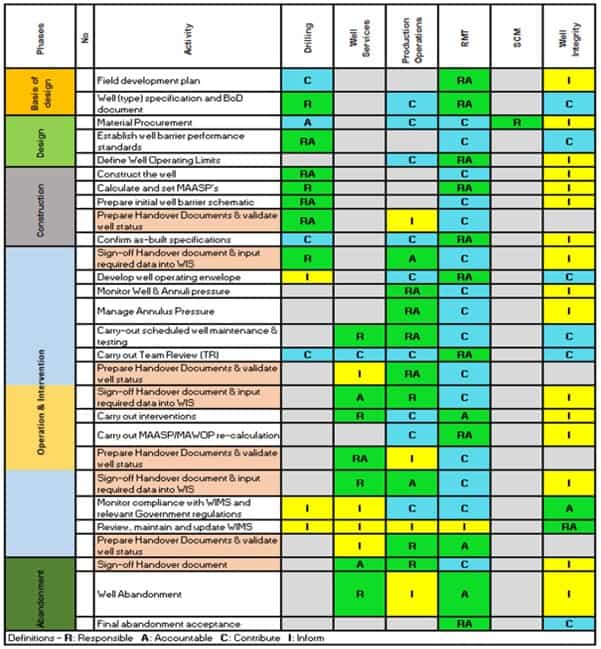

The session highlighted the risks associated with poor well integrity, such as the potential for hydrocarbon leaks, which can have catastrophic environmental and safety consequences. The second part of the session discussed the roles and responsibilities of various stakeholders in ensuring well integrity management.

The session emphasised the importance of collaboration and communication between different departments and contractors to achieve well integrity throughout the well’s lifecycle.

The session aimed to promote a proactive approach to well integrity management, encouraging participants to consider and question the methods used to ensure well integrity.

Overall, the session’s objectives were to provide participants with the knowledge and tools necessary to manage well integrity effectively, ensuring the safety and sustainability of oil and gas operations.

By understanding the importance of well integrity and how it can be achieved, participants became better equipped to manage the risks associated with oil and gas operations and ensure the longevity of these operations.

Well Integrity Regulations

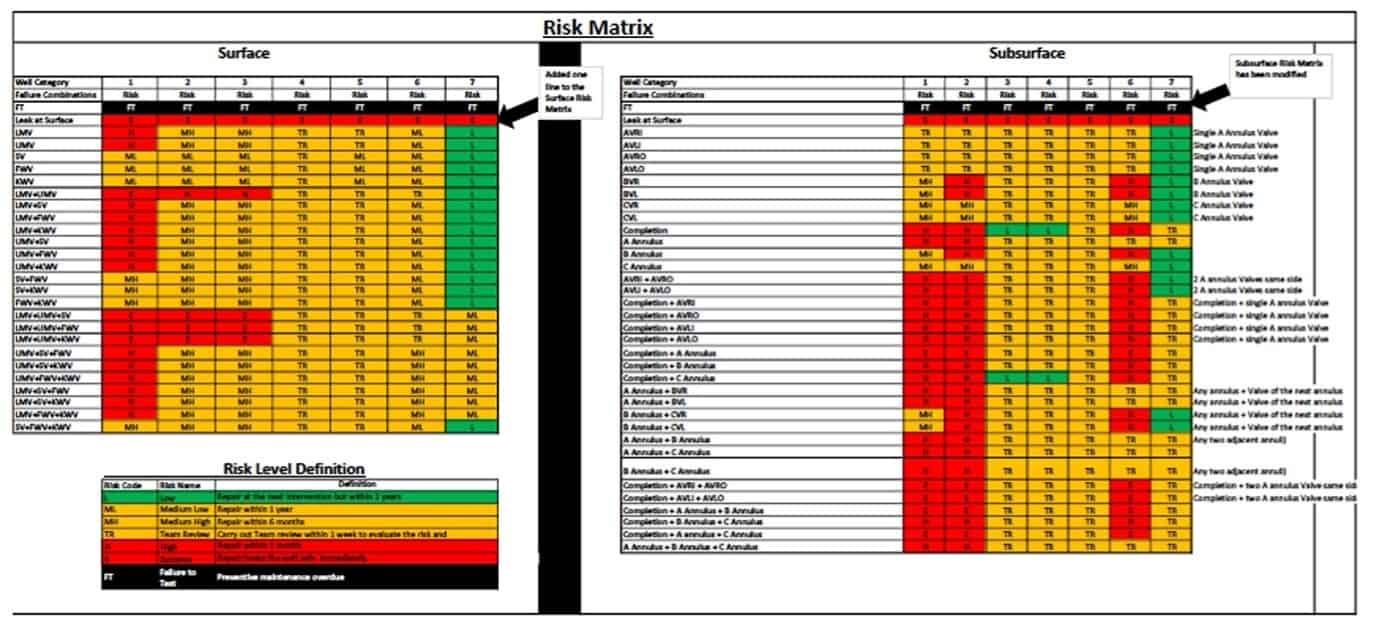

Article 7 of the MOG Regulations outlines the requirements for oil and gas operators to ensure well integrity during drilling and production activities. The article covers various aspects of well management, including casing and cementing requirements, well control procedures, and pressure testing procedures.

According to the article, operators must ensure that the casing and cementing of wells are designed, installed, and maintained per industry standards and best practices. This includes ensuring that the cement used in well construction is of high quality and is properly placed to prevent leaks or fluid migration.

Additionally, operators are required to have well control procedures in place to prevent well blowouts or other well control incidents. These procedures should be regularly reviewed and updated to reflect changes in technology or operational practices.

Finally, the article outlines the pressure testing requirements for wells, which are designed to verify the integrity of the wellbore and prevent the escape of hydrocarbons or other fluids. These tests must be performed at regular intervals and must be conducted by qualified personnel using approved testing equipment.

In summary, Article 7 of the MOG Regulations requires oil and gas operators to take measures to ensure the integrity of wells during drilling and production activities. These measures include casing and cementing requirements, well control procedures, and pressure testing requirements. By adhering to these regulations, operators can help minimise the risk of well failure or other well control incidents, which can have serious environmental and safety consequences.

Initial Findings

The organisation had made significant progress in ensuring well integrity. They put in place a Well Integrity Management Standard and developed a Well Integrity Software System.

Additionally, the organisation successfully tendered for pump units to assist with routine well integrity testing and has developed guidelines for Well Suspension & Abandonment.

They were building a Well Integrity Team to provide support to responsible departments and have started a programme to roll out standards and increase awareness.

The organisation has also provided feedback to MOG on proposed Regulations & Guidelines. Overall, the organisation was taking proactive steps to ensure the integrity of their wells during drilling and production activities.

Steps Towards Complete Well Integrity

A technical review was carried out by our Well Integrity team with a focus on past documentation and the current state of play. We provided a detailed gap analysis report, as well as recommendations to address the gaps covering all aspects of the Well Integrity review, including findings, training, planning and evaluation.

The purpose of this document was to define how the IOC manages the integrity of its well stock throughout the lifecycle of the well and to set out the responsibility and accountability of the departments for delivering necessary well-integrity assurance. It followed ISO 16530-1 2017 Well Integrity Part 1 – Life Cycle Governance concerning the IOC company policies, procedures, and guidelines (PSPGs) and other key industry standards where applicable.

At the end of the Basis of Design , Design & Construction Phases

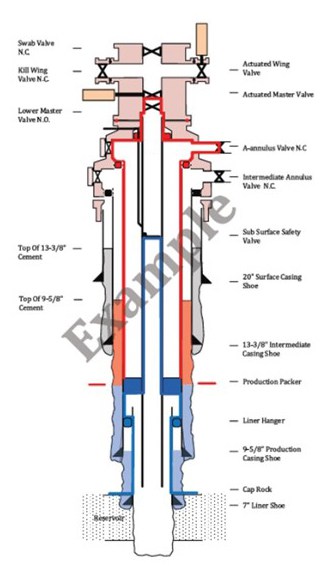

The well was designed and built following the company’s Well Construction PSPGs. That ensured that the well was constructed to the highest standards of safety and quality. The well design also ensured that the well could be effectively abandoned at the end of its life. This is important to protect the environment and to prevent the well from becoming a hazard. The well barrier verification process is documented to ensure that the well meets the life of well objectives.

This process includes testing and verifying the well’s barriers to ensure that they are effective in preventing leaks and spills. The risks associated with the well were assessed and mitigated to reduce the associated risk to ALARP (As Low As Reasonably Practicable). That ensures that the well is operated safely and responsibly. The well was validated by the Subsurface Department to ensure that it met the original functional specification. This validation process included testing and verifying the well’s performance to ensure that it meets the requirements of the operator. The key requirements for the well were:

- The well must be designed and built in accordance with the company’s Well Construction PSPGs

- The well must be designed to be effectively abandoned at the end of its life

- The well-barrier verification process must be documented and completed

- The risks associated with the well must be assessed and mitigated

- The well must be validated by the Subsurface Department.

The following information must be available prior to well handover:

- The details of the MAASPs (Minimum Allowable Annulus Surface Pressure) and well-operating envelopes

- The specified operating and maintenance requirements

- The complete and accurate documentation for well-barrier verification

- The complete and accurate well-barrier schematic

- The complete and accurate well handover documentation.

This information is essential to ensure that the well can be operated safely and effectively.

Deliverables

Our main deliverables were:

- Submitted a report commenting on existing documents and providing further guidance to improve them

- Providing support in the preparation of the Well Integrity Testing Guidelines

- Review Suspension & Abandonment SOPs

- Be on call in the subsequent months for any amendments required.

- Conduct a Review of Well Integrity Failures and Investigations.

Conclusions & Recommendations

As a result of the reviews and consideration of the selection criteria, it was recommended that the IOC continue their current approach in maintaining and improving well integrity. This includes maintaining adherence to the Well Integrity Management Standard and making use of the Well Integrity Software System, both of which have shown to be instrumental in ensuring operational safety and efficiency.

Work completed by: Gordon Duncan

Well Operation Case Study

Well integrity, Completions, Interventions & abandonment Expert

Gordon Duncan

Do you think that Gordon has something to offer for your project? Perhaps you have something to offer Gordon?

If so, then fill in this webform and Gordon will be in touch with you as soon as possible.

In the message box, please indicate the reason for the enquiry in simple and precise terms.

Privacy notice: Rest assured that only Gordon Duncan, and up to three integral personnel at drillers.com will see your contact details. We won’t distribute these details or add you to any mailing list without your explicit additional consent.