Statement of Findings

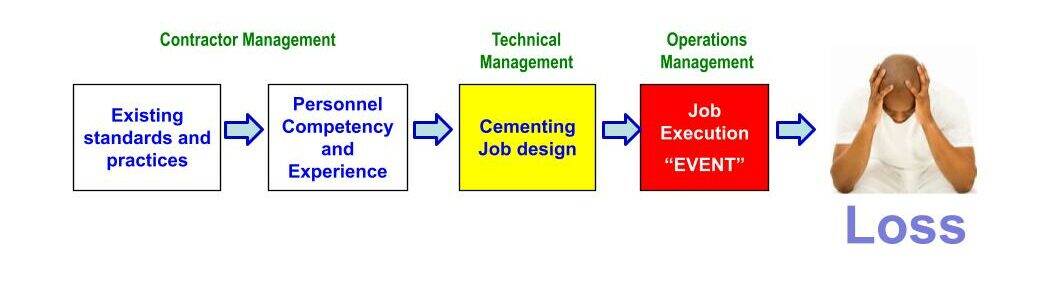

We presented a detailed analysis of four wells: A, B, C and D. For each well, we scrutinised various aspects such as job design, execution, and cementing job specifics. We delved into root cause analysis, exploring factors like personnel competency, existing standards, and management practices.

We provided insights into the technical and operational challenges encountered in each case, highlighting areas for improvement to enhance future cementing operations.

For Well A and B, the focus was on simple cementing objectives like top of cement (TOC) and isolation of perforations. However, there was no mention of zonal isolation above, across, or below the region, nor of any other permeable zones.

In contrast, for Wells C and D, we delved into the specifics of each operation, assessing the design, execution, and outcomes. We revealed key insights into the successes and challenges faced, underlining the importance of meticulous planning and execution in cementing operations.

This comparative approach highlighted the nuanced complexities inherent in each well’s cementing process.