© Copyright 2024 Drillers.com all rights reserved. Terms & Conditions Privacy & Cookie Policy Web Design

Discover the Power of Geomechanics with Merlin

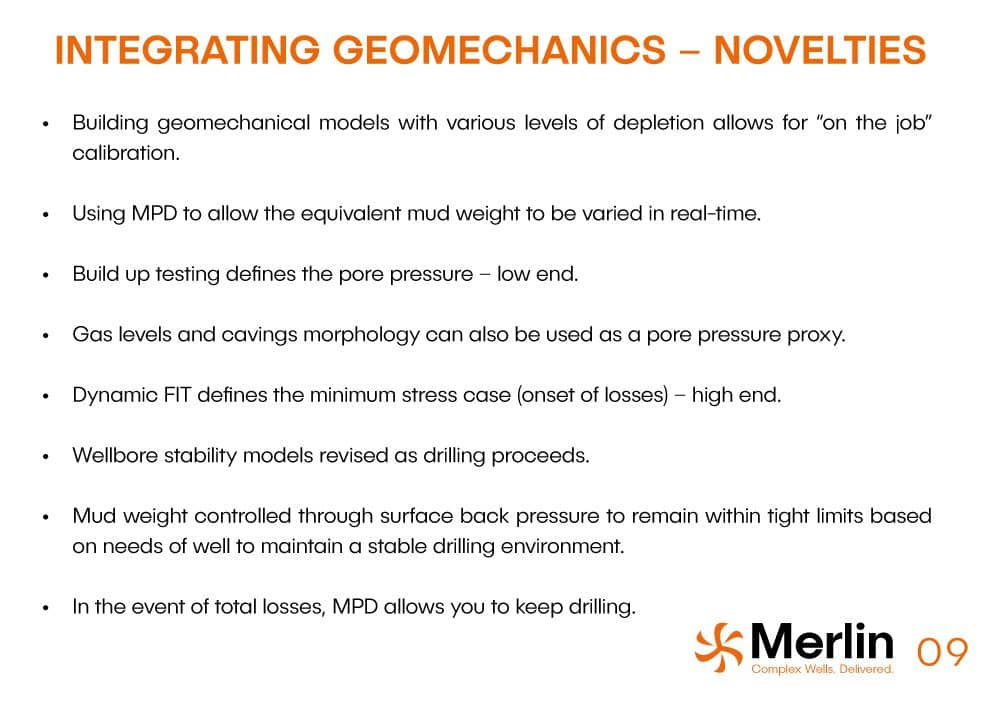

Merlin provides a comprehensive range of geomechanics engineering services, practical training, and operational support. Merlin's focus is on managing wellbore stability, dealing with real-time risk management, and offering relevant training to enhance your team's capabilities. With Merlin's guidance, you will be better equipped to understand your subsurface system's constraints, plan effective well designs, and handle potential drilling complications efficiently.

Explore Our Key Services

Wellbore Stability modelling:

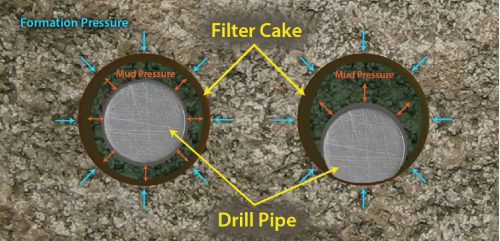

One dimensional (1D) poro-elastic models are built and calibrated based on field data to enable the drilling team to understand the limits the subsurface environment imposes of their loading envelope. A comprehensive report has been generated, providing detailed information on offset wells used for calibration, rock properties utilised in the modelling (including limitations and assumptions), pressure gradients, definition of mud weight limits through the creation of stereo plots, and an assessment of the impact of drilling fluids on rock strength. This aspect is particularly crucial but often overlooked, contributing significantly to a thorough understanding of wellbore stability in deviated hole sections. The recommendations presented in our reports are not mere rocket science; rather, they are rooted in the practicalities of drilling high-angle and extended-reach wellbores, ensuring reliability.

Risk Mapping:

Following the development of a wellbore stability model, we can take the outputs and use them to build a roadmap for drilling the section based on the likely occurrence of cavings. We integrate uncertainty in pore pressures, collapse gradients, fracture and stress fields to provide you with a tool which will enable proactive hole condition management and give early warning of potentially adverse drilling conditions.

Upskill with Merlin and learn to drill further, faster, more efficiently.

Invest in yourself, your team and ultimately your results by attending Merlin’s Geomechanics Training Course. The content is intended to be of practical use, with a focus on real-world examples and case studies, rather than the mathematics behind the subject.

What will I learn?

-

The importance of understanding subsurface stress regimes and what can happen if these are ignored in well planning.

-

How a geomechanical is built and calibrated.

-

Fundamental features of the models.

-

How the wellbore interacts with the subsurface stress field.

-

How to optimise the well design and execution plan based on the model outputs.

-

Benefits of real-time monitoring and model updating to optimise the drilling program.

Sample Schedule

- Tue: 8am – 16.30pm

- Wed: 8am – 16.30pm

- Thu: 8am – 16.30pm

Who Should Attend?

-

Drilling engineers.

-

Geologists.

-

Reservoir engineers and other professionals involved in well construction operations which are likely to have some element of risk associated with a known or a potential wellbore stability problem.

Day 1 – Introduction & Fundamentals:

Day 2 – Fundamentals:

Day 3 – Drilling Fluids, Risks and Equipment

Day 4 – Operational Factors and Challenges

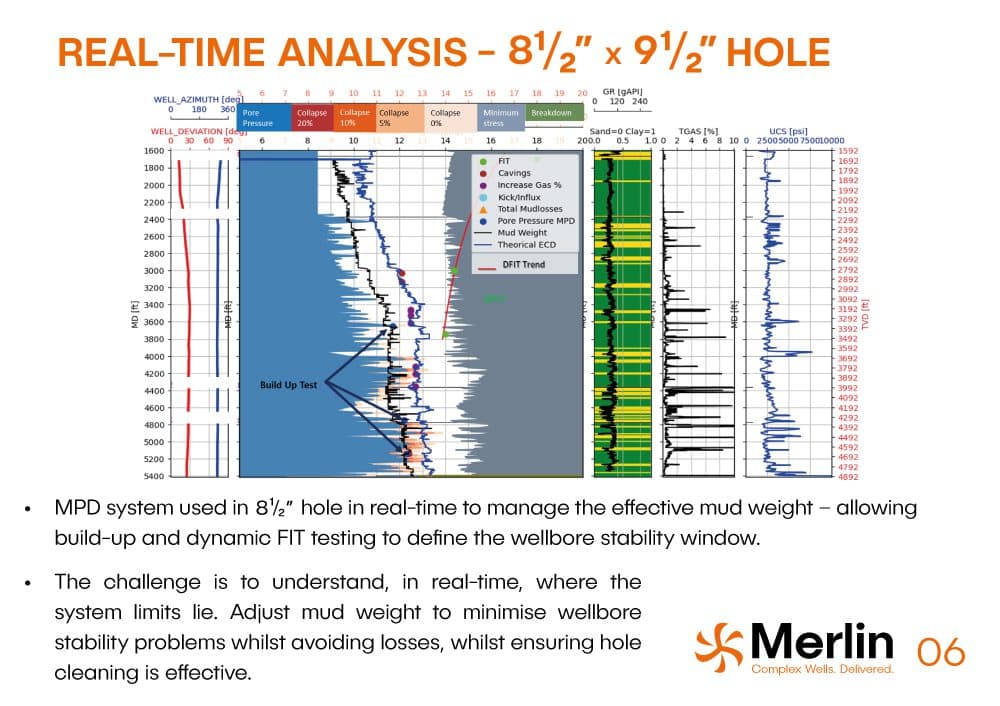

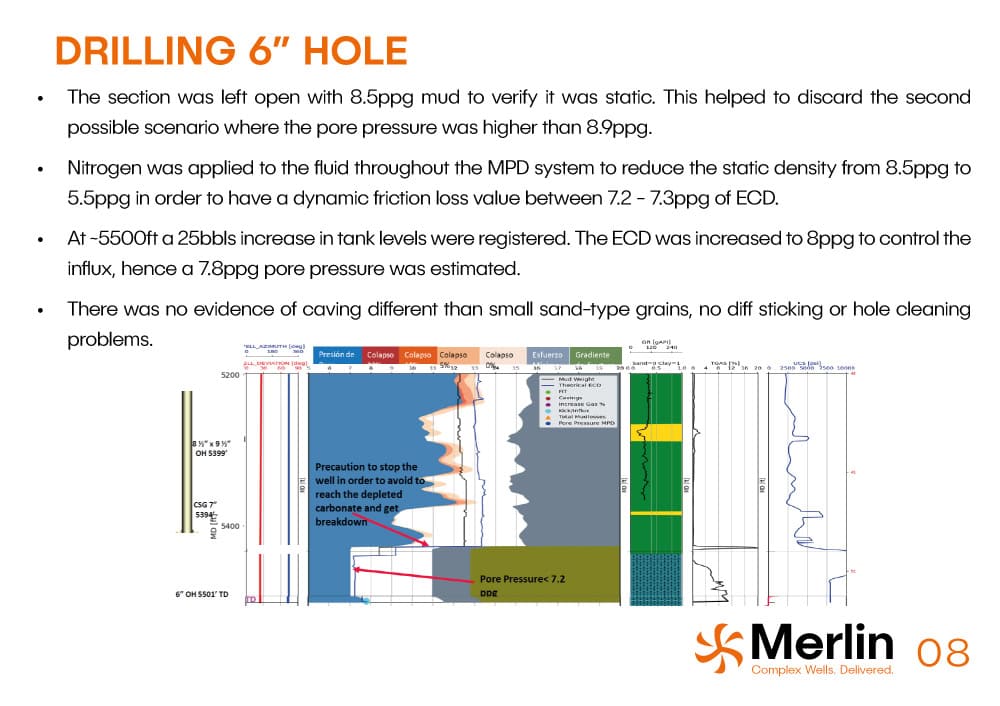

Real-time management and optimisation:

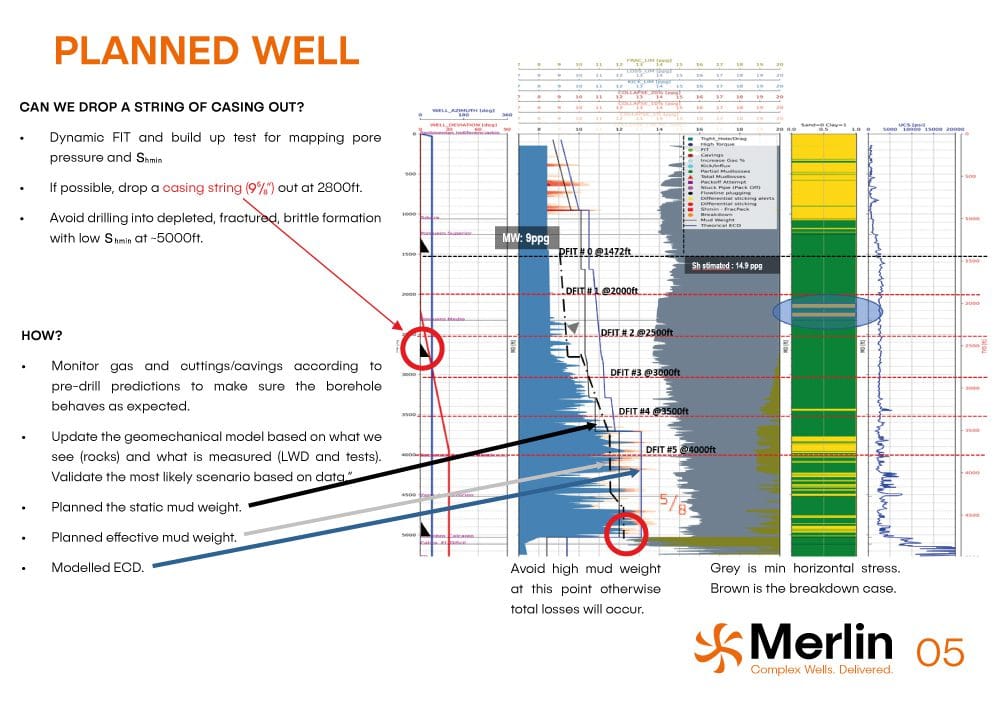

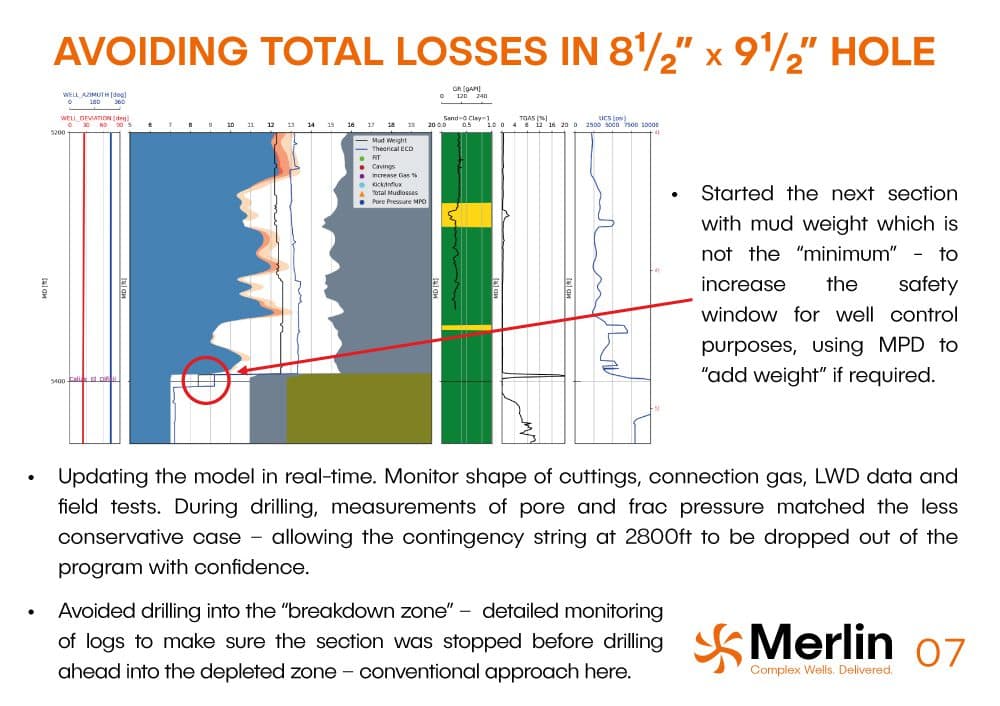

A natural extension of modelling and mapping, having geomechanics engineers monitoring operations in real-time ensures that models are updated in response to observed data, reducing uncertainty and improving the likelihood of a problem free well. This is particularly useful where there is uncertainty in pressure gradients which could lead to commitment of an unnecessary contingency casing string, or conversely, being able to drop a string given the right set of conditions and observations. Having early access to data may allow designs to be simplified reducing project time and cost, while improving overall project value.

Onsite geomechanics engineers will also be able to provide support for unusual drilling operations such as low energy drilling (LEDO) where system energy is minimised to avoid aggravating existing wellbore stability problems (e.g. fissile formations, existing plane of weakness instability). Understanding the volume of cavings compared to cuttings, how it evolves, and its implications in relation to system limits is an excellent tool for mitigating risks associated with complex drilling problems.