A wellbore cleanup roadmap…

I have been involved in cleaning up oil and gas wells for over twenty years now, sometimes going from one to the next without a break. For years. I like to think that I’ve learned a thing or two along the way. One thing I learned first rattle out of the box is that virtually everyone you meet has their ‘surefire’, ‘can’t miss’ recipe for implementing this stage of completion operations.

Most times, if you dig a little bit you will find that a lot of their information comes from anecdotes, or ‘rules-of-thumb’, and are very light on practical experience. Stuff like;

Spacer sizing- “You need a 1,000’ of separation in the largest annulus. Let’s do 1,500’ just to be safe.”

Simple solution- “Just pump caustic. It’ll be fine.”

Magic cleaner- “This stuff is so strong that five-minutes of contact time is all that’s needed. Dirt just floats to the top.”

Is there any science or technology in any of the above statements? Nope.

Even today, when the wellbore cleanup industry has actually evolved to a fairly high level of competence, you still hear stories of displacement disasters. Leading me to ask, why? That’s a big question. I find sometimes the easiest way to get your head around big questions, is to break them up into smaller questions, and tackle them sequentially, sort of like a process. Something we are about to discuss.

My goal in writing this article is to give the new folks in this business, who will be performing these displacements out on the rig, a roadmap to a successful outcome; a Process, if you will. Following a process forces us to organize our thinking and gives us waypoints to measure our progress as we implement each stage of the process.

Hopefully, by the time you finish this article these, ‘rules of thumb’ will seem as silly and out of date to you as they do to me. If that proves to be the case, at least some of the drama will be taken out of this operation.

So let’s begin. As noted above, I am big on process when I approach a task, an outcome of my Big Color background I am sure. The first step in a process is figuring out what a successful outcome will look like.

What is the task at hand?

Well bore cleanups are often called displacements as they involve the removal of one fluid with the installation of another. In completions the task in a displacement is to deliver a clean, obstruction-free well bore to the lower completion team. Key Performance Indicators (KPI’s) of success include:

- Interface between fluids of less than ten percent of the openhole volume with pipe.

- No shutdown of pumping once the displacement has begun.

- Clean, filterable fluid back to surface in one and a half hole volumes.

- No recharge of filtration media during the pumping operation.

- No mud on tubulars withdrawn from the well.

Those are the biggies, there are others, but if we hit those targets our well bore clean up (WBCU) is likely to be judged a success.

OK, keeping our task of delivering a clean, trouble free well bore to the client in mind, and those KPI’s on a sticky yellow Post It where we can see them easily for reference, how do we go about it? What’s the first step?

The industry has established a methodology that consistently delivers a clean, trouble free well bore when it is rigorously followed. It includes three separate, but equally important factors. Let’s look at a short definition of each.

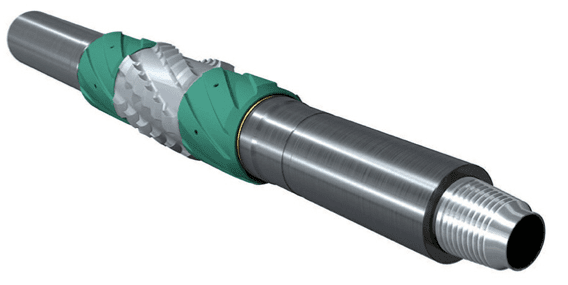

Mechanical– an optimized combination of casing scrapers, circulating subs, debris baskets and downhole filters, and magnets that are used to: dislodge cutting beds, scrape packer setting areas, reduce mud film on tubulars to absolute minimums, and physically extract debris that cannot be removed with flow rate.

Chemical– use of targeted chemistry to minimize interfaces between the fluids being displaced and the fluid being installed; control and degrade any emulsion tendencies between the spacer train and other well bore fluids; water-wet tubulars.

Hydraulics- use of computer modeling to predict engineering values in the well bore geometry as the spacer train is pumped through the well.

Mechanical effects

When we go into a well it is very likely that there will be debris from the drilling operation left behind. This can be cement sheath, settled cuttings beds, ferrous material from pipe rotation; all of it is classified as debris. We need to get that debris out of the well to meet our task of delivering an obstruction free well bore to the client.

Scrapers are included in the work string to remove loose, or packed debris that might impede access to the well bore. This is an important step in incorporating this debris in the mud system for removal. I will touch on this concept for a moment here as it is really important. Spacers are not going to remove large amounts of solid debris from the well bore. That just isn’t their job. I’ll bet I am surprising, or shocking some of you now. Just please accept this for now, I will develop this idea in more detail in the chemicals section of this article.

(Photo courtesy of Odjfell Well Services)

Pipe movement is next on the hierarchy of solids transport. A little bit of physics as pertains to solids-as they succumb to gravity solids form gel structures that must be broken in order to break circulation. This is also a dynamic process, meaning that even after the initial gels are broken and circulation begins, solids will again settle given the opportunity. In order to get them out of the well we must deny them that opportunity by moving the pipe. Pipe movement-rotation and reciprocation is your best chance to remove solids from the well. Believe it.

Circulation subs and baskets also contribute to mechanically removing debris from the well, and are often used in conjunction with one another; i.e. a basket or downhole filter above a circulation sub to increase annular velocity (AV), and physically trap debris to be removed as the work string is withdrawn from the well.

Final thought here. I know budgets are tight right now. Trust me on this, you need the help that scraping, brushing, and pipe movement will provide to deliver your clean, trouble-free well bore to the client. They are worth the money and the time spent. Fight the good fight with the budget trolls and insist on them.

Chemicals

As I write this, I have my stereo turned up, listening to Jimi Hendrix’ Voodoo Child. What an appropriate choice to begin the commentary on the chemical clean up! I don’t know of any other segment of the oilfield service industry that suffers from as much misinformation, mysticism, half-truths and out-right balderdash as the chemicals used in spacer trains. There’s a lot of Voodoo out there, but it doesn’t have to be that way. I am going to take the high road here and just tell you what has worked pretty well for me in the countless wells I have cleaned up over the last twenty years, or so.

I was part of a team at a Big Color mud company about twenty odd years ago that began to investigate ways to standardize chemical WBCU’s. Some of this impetus was driven by clients who wanted to be able to expect that similar operations would follow the same guidelines regardless of personnel or geographic location.

Sounds reasonable, doesn’t it?

Competitive pressures also played a role in this investigation. We were spending huge amounts of money doing deep water displacements and we had a lot companies gunning for us.

We spent several years and studied spacer flowback samples on some forty-plus wells, and learned a lot. The results were published in series of really excellent SPE papers, and I’ll list the numbers if you would like read in more detail. Proof that we had hit on a reproducible way to displace oil wells was the fact that most other companies soon adopted our methodology. They say imitation is the sincerest form of flattery!

For those who aren’t ready to spend that kind of time, here’s what we learned.

The lead spacer should be made of the base fluid that is used for the mud. If you are using a water based mud, then a volume of brine or drill water is appropriate- density dependent. If you are using an SBM, then a volume of base oil should go down the well first.

The next spacer is generically called a ‘Push Spacer’. We found that this spacer should be highly viscous, and be weighted at least 2-ppb over the mud weight. In the case of an oil-based displacement it should also contain chemistry to break down emulsions that would tend to form with aqueous fluids. This spacer was viewed by us as the most important part of the chemical WBCU. It did a number of jobs as it was pumped around the well.

- Acting as a piston, it pushed the fluid being displaced ahead of it, minimizing channeling that could contaminate the cleaning spacer.

- It was the heaviest, thickest fluid in the pipe. As the pipe was rotated these attributes helped it to low side the well and incorporate solids in the main fluid stream.

- The chemicals that made the spacer compatible with the other well bore fluids, enabled the minimization of emulsions, or viscosity humps that could prove catastrophic to the success of the displacement.

- It also started the water-wetting process on the pipe that enabled loosely attached solids to be moved out of the well with flowrate.

The cleaning spacer was pure chemistry in a turbulent flow regime. The actual amount of chemical was determined via testing in the lab. We would usually test 5-20% concentrations at various bob speeds to land on this. With most muds we had complete cleaning in a couple of minutes at a 100 RPM with 10-15% active chemical. We chose 100 RPM to minimize the impact of turbulence in the test. And, then we would check to see if it continued to clean after being contaminated with 10-20% mud.

What is important to understand about the cleaning spacer is it is intended only to tackle a thin film of mud left behind after the compatible push spacer. It should be formulated to clean after it incorporates mud as previously stated. But, if mud channels back, the cleaning spacer will be overwhelmed, and mud will re-coat the pipe, leading to a bad day in the oilfield.

A note on cleaning spacer chemistry. For SBM we found that ‘Double Emulsion’ chemistry worked best. This is created by using a combination of a terpene solvent and surfactant blend together. There many SPE papers about creating this effect authored by many service companies, and I will include a reference to one at the end of this article. For a water-based system, a high pH detergent worked best.

Finally we would pump a viscous spacer to act as a ‘sweep’ for any loose debris that remained behind.

I have personally used this spacer train dozens of times in deep water and on land, and can attest as to its efficacy.

Hydraulics

Computer modeling has changed all aspects of modern life, and probably nowhere more so than in the oil industry. Displacement modeling enables us to gauge the impact of various fluid rheologies through the pipe geometry, at programmed pump rates. From it we get critical information: HHP requirements, max pump pressures, ECD’s, flow regimes and so on. This technology has reached the high-art stage of development and there are many platforms out there. Use one.

Best Practices

There are many, but I am going to focus on the most important item here for the sake of brevity.

Arguably the most important factor in a successful mud displacement lies in the ‘conditioning’- or circulation of the mud to break gels, and incorporate solids into the fluid stream, of the mud prior to pumping the spacer train. I highlight this because nearly every time I attended a DWOP, CWOP I had to defend this practice because it took time on the Critical Path.

The comment would come, “we’re paying money for your cleanup chemicals. If they do their job, we shouldn’t have to waste time circulating on bottom.”

If you have read this article carefully, then you probably know how I responded, so I won’t repeat it.

Let me emphasize to you, because at some point you will be in my position-

THERE IS NOTHING MORE CRITICAL TO THE SUCCESS OF THE DISPLACEMENT THAN CIRCULATING THE MUD ON BOTTOM, PRIOR TO PUMPING THE SPACER TRAIN WHILE ROTATING AND RECIPROCATING THE DRILL PIPE.

Any questions on that point?

Good.

Final thoughts

I’ve put out a lot of information here, but it’s pretty high level. To give you an indication of how high level, I have taught week-long classes on this topic. So, put that into perspective. There’s a lot we can’t cover in a short article.

The idea here was to give you a glimpse at a successful process for removing mud and installing completion fluid into a well. Let’s recap quickly-

Objective- Delivery of a clean, obstruction free well bore to client

Resources-

- Mechanical effects- scrapers, circulation subs, magnets, debris management subs, pipe movement

- Chemicals- designed into a spacer train that designed and lab tested for functionality

- Hydraulics- understood for each well modeling spacer properties in a specific well geometry

Measurement metrics- KPI’s

Results- Delivery of clean, obstruction free well bore

One caution. If reading this article represents the bulk of the time you’ve spent studying WBCU’s, you’re not ready yet to go out and do one. If you have responsibility for a WBCU on your horizon, I strongly suggest attending formal training on this topic taught by someone who has a few of these under his/her belt.

Acknowledgments and further reading

I had the good fortune to be part of the team that did most of the work I’ve summarized in this article. My own role was fairly small. Without the leadership of Bill Foxenberg, and Mike Darring, and the contributions of David Kippie, Clay Lockett, Neil Cerny, John Carboni, and others, we wouldn’t have gotten as far as we did. Those guys will always have my gratitude and respect!

SPE/AADE papers: SPE-73711, 151604, 86496, 110589, AADE-04-DF-HO-39. These are some of the best and will give you a good overview of WBCU’s.

Hi Dave.

I would like to discuss options on how I can further develop my knowledge on WBCU. I have some experience with WBCU operations but would like to learn more as this is the department I wish to thrive in. Your help is appreciated.

Jonny

Hey Jonathan, I commend your desire to learn. Everybody starts out where you are in this business. You’ve made a start just by reading this article. Probably the best way to learn is get hired by a company doing well bore cleanups. There are a bunch of them out there. I’ll be glad to answer any specific questions you may have, and I’ll be writing more articles on this topic. So stay tuned. Cheers, Dave Messler

Dave: simply brilliant, and it is a not well know art . Your knowledge and experience is very valuable. Congratulations and I am sharing the article in english and spanish.

Mauricio, you are too kind. Thanks for sharing. Let me know if I can be of any help to you. I will be posting more articles on this site soon. Cheers!

Dave,

Good article.

The original work that changed the industry came from Shell UK with BP input, in the late 90’s. It was realised how much NPT was being lost as a result of poor WBCU operations and a team, of which I was part, was formed to develop solutions. After much mechanical, laboratory, and chemical work plus computer simulations, various dowhole tools and chemical trains were developed. This was proven in the field where NPT was drastically reduced. A manual called the ABC of Wellbore Cleanup was issued which provided all of the background, tips and procedures. I am sure this is still around in one form or another.

When I went to Deepwater GOM in 2002 with BP Thunderhorse they were experienced similar issues but with added complexity due to the deep wells and the large volumes involved. The procedures, mechanical tools and the chemicals being used at that time were simply not able to cope. However with a change of downhole tools and then lab work from MI, namely Bill Foxenberg, Neil Cerny etc we were able to resolve the problems. Together with the learnings from the ABC of Wellbore Cleanups, new procedures were developed which eliminated the associated NPT. This allowed Thunderhorse to move towards best in class. I just hope these learnings are not lost when this generation retires from the industry.

Hey Burnie, thanks for your in-depth comment here. You and I were at BP GoM at the same time. I worked with Tammy Webb’s team on the King and Nile subsea projects among others. My last BP project was Holstein. Small world. I am surprised we never crossed paths.

I am very familiar with the Shell ABC manual, and on reflection, should probably have mentioned it in this article. What’s interesting, and related to your final comment, is that it seems to have slipped from institutional memory with in that company, to some degree anyway. I worked for Shell in Brazil for over four years and never once had it mentioned as a resource. I have put on WBCU lectures in Shell organizations several places around the world where I mentioned this resource to the surprise of some in attendance. This could just be the way of the world.

Being in the semi-retired ‘geezer’ class of oilfield professionals, I take as my primary mission to try and minimize this effect in the new people joining the industry. Hoping to pass along some lessons of my thirty-eight year career. It goes in fits and starts as you might imagine.

Thanks again for engaging on this article.